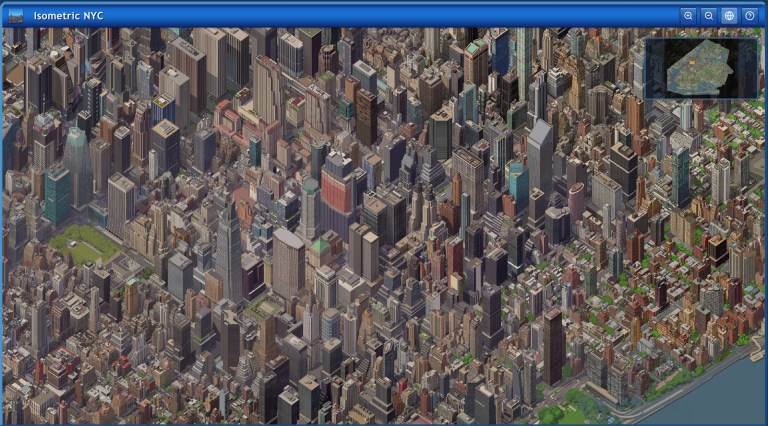

A Fascinating Behind the Scenes Look at the Cobbs Lane Factory Where Doc Martens’ Shoes Are Made

Insider took their cameras inside the famous Cobbs Lane factory in Wollaston, Northamptonshire to give a fascinating behind the scene look at how the iconic Doc Martens’ shoes are made. Production manager Stephen Bent quite affably explained each step of the process, which includes cutting the leather, sewing the pieces together, adding stitches to strengthen the shoe (including the distinct yellow stitches) and stitching PVC all the way around the shoe upper. Bent stated that this what makes Doc Martens’ different from other brands.

We do things differently. We stitch a PVC welt all the way around the upper. The sole and the welt are melted together without using adhesive. Because there’s no glue involved it means the welt can’t come unstuck. Basically we’ve taken it high above its melting point, squeezed it together while it was liquid and as it cools it cools it becomes one piece of PVC.

After that, the shoe is trimmed, checked, cleaned, polished, laced and boxed for selling. This factory creates all the “Made In England” branded shoes and is only a small part of the Doc Martens’ empire.

This is where Dr. Martens makes its iconic “Made in England” collection. The factory employs 50 workers that make about 100,000 pairs of boots per year, which is only one percent of what the brand makes as a whole!

via The Awesomer